This post has nothing to do with anything I've made or modified, but I feel like sharing it anyway.

Last year (2010) over Thanksgiving weekend my mother flew out to visit some relatives on the East Coast. One of my (many) weird quirks is that I enjoy taking people to and from the airport.

So what does this have to do with anything? Well, I listen to a lot of podcasts. One of my favorites is the Drunk Tank, the podcast of Rooster Teeth (a machinima company whose many products I enjoy). On one particular episode one of the podcast members mentioned that he had been in Seattle and really wanted a burger and thus tweeted the inquiry of where to go, and was quickly pointed towards a place called Lunchbox Laboratory (lunchboxlaboratory.com). He then said it was the largest, most delicious burger he'd ever eaten.

Since I hate driving myself around, I wasn't willing to go up to Seattle to find this place for the hell of it. However, thanks to my mom's flight back from the East Coast, I was going to be in the area anyway. Happy times!

Anyway, this place let you choose either a "stock" type of burger (cheeseburger variations, veggie burger variations, etc) or you could build your own from a massive variety of ingredients. Lacking hudspa I went with a stock burger (I don't recall which one), and this is what it looked like.

As it should now be obvious, there's a lot of stuff in there. And it was amazingly delicious. Seriously. Here's another pic that should better emphasize the height of this bad boy with a decent cross-sectional view thanks to my already having eaten some of it.

There was a lot of burger there, but I ate it all without incident. The only real problem I had was starting into it without causing some innards to spit out the othe end. You know, the usual difficulty with anything thick like this. In any event, it was great. Once my braces get off, I plan on trying this burger the Ram offers called the Behemoth. Supposed to be crazy huge. We'll see how that goes.

Wednesday, June 22, 2011

Friday, June 3, 2011

Cat Bowl Stand

So, I have a cat. Because I live in an apartment, I decided to get a pet, and went with a cat instead of a dog because cats can be litter box trained. Dogs need to be walked, and all that fancy jazz. Anyway, after having her for a couple months, Tess started barfing regularly. After some research I learned that all cats belong to one of three categories. 1 - they do the hairball thing. 2 - they barf. 3 - they do neither, and you're super lucky. Well, my cat is a barf machine. There wasn't a week that went by without my returning home from work to find a large floor present of the unwelcome kind on my carpet. So, I'd clean it up and get on with things. I even got a steam carpet cleaner from my parents for a holiday present a few years back, so the cleanup was even easier. I also (through trial and error) found a kind of cat food (Purina Sensitive Stomach) that made it so she only barfed once every 2-3 weeks. Then I read somewhere (wish I could remember where) that a common cause of feline vomiting is from bending all the way down to the ground to get at their food/water bowls, and that if those bowls are raised up an inch or two, their digestive systems function amazingly better.

Since I'm in a big DIY period of my life (and also because the bowl stands I saw in stores were butt-ugly), I decided I could make a stand for Tess' bowls, and see if it made a difference in her vomit regularity. Even if it didn't, it would mean that she couldn't shove her bowls around on my carpet and spill water and/or food quite so easily, so it was a win-win scenario for me. And thus, I was off to begin working! But first, a picture of the recipient of this project.

My procedure for this was pretty easy, as all I had to do was take some measurements of the bowl dimensions, and decide how high I wanted them off the ground. With that done, I turned to my dad, who has tons of scrap wood lying around the house (why? no idea). What I ultimately used was a big piece of particleboard covered in formica.

It might be a bit hard to make out the specifics, but I took my dad's large L-square and drew out the dimensions of each piece right onto the formica top in pencil. The two paper cut-outs are sized for the eventual holes the bowls will sit in. I'm not good at freehanding circles. With the dimensions laid out, it was cutting time.

At this point I've cut out each "leg" of the stand, and I'm currently using the band saw to cut around the circle lines I drew out with the paper markers. It's easier than you might think, you just drill through the wood with a large bit (I used a 1/2") and then start cutting from that point. The saw can make turns quite easily, and then it's just a matter of following the lines.

This is what one of the legs looks like. The other leg looks exactly the same. Fancy that, right?

Oh look, big hole cut-outs! I wonder where they came from...

And now we see the bowl stand in all of its unfinished glory. The pieces have been cut out, but that's it. Very rough, and with the formica still covering most of the surfaces, gluing them together wouldn't work very well.

So, at this point what I did was clamp the two legs together in an attempt to make them as identical as possible. With them clamped together I went over all the edges to do just that. Lots of sanding time, essential for any project.

With the legs matching up a bit better, I took all of the pieces outside with the belt sander, and removed the formica. It didn't take all that long, but my methodology wasn't perfect, and so some places on the top had peaks and valleys from a lack of uniform sanding. You can't see it, but they're painfully obvious to the touch. Regardless, the stand is pretty much done at this point. All I had to do now was use some wood glue to attach the legs, and it was showtime!

It took Tess a little bit of time to get used to eating out of it, but she adapted quickly. Perhaps more importantly, since I completed this prototype and started using it back in November/December of 2010, from then until now (June 3rd, 2011) Tess has barfed exactly ONCE. So I'd say either she a) grew out of barfing as a natural part of growing older, or b) the bowl stand has done exactly what I wanted, and brought the vomit occurence rate as close to zero as I could have wanted.

So, there are a few problems with the design. First, because the ends are uncovered, Tess can sometimes knock a toy underneath the stand, and I've had a few annoying moments where, in an attempt to get at the toy, she will knock the water bowl out of the stand and onto my carpet. Second, it's not very pretty. I'm not really into aesthetics as a general philosophy, but with the peaks and valleys in the top piece, as well as the unfinished wood look, I'll probably want to revisit this project at some point. Third and finally, Tess is a very messy drinker. I know, I know, cats are supposed to be very clean creatures and all that. Mine isn't. She constantly gets water out of the bowl while she's drinking, and I know that over the long haul, that will eat away at the wood, causing warping and overall structural instability. So what does all this mean? Mostly just that this project is only finished "for now" and will have to be revisited in the future to fix some of these problems. But for now, this prototype works amazingly well and I couldn't be happier.

Since I'm in a big DIY period of my life (and also because the bowl stands I saw in stores were butt-ugly), I decided I could make a stand for Tess' bowls, and see if it made a difference in her vomit regularity. Even if it didn't, it would mean that she couldn't shove her bowls around on my carpet and spill water and/or food quite so easily, so it was a win-win scenario for me. And thus, I was off to begin working! But first, a picture of the recipient of this project.

My procedure for this was pretty easy, as all I had to do was take some measurements of the bowl dimensions, and decide how high I wanted them off the ground. With that done, I turned to my dad, who has tons of scrap wood lying around the house (why? no idea). What I ultimately used was a big piece of particleboard covered in formica.

It might be a bit hard to make out the specifics, but I took my dad's large L-square and drew out the dimensions of each piece right onto the formica top in pencil. The two paper cut-outs are sized for the eventual holes the bowls will sit in. I'm not good at freehanding circles. With the dimensions laid out, it was cutting time.

At this point I've cut out each "leg" of the stand, and I'm currently using the band saw to cut around the circle lines I drew out with the paper markers. It's easier than you might think, you just drill through the wood with a large bit (I used a 1/2") and then start cutting from that point. The saw can make turns quite easily, and then it's just a matter of following the lines.

This is what one of the legs looks like. The other leg looks exactly the same. Fancy that, right?

Oh look, big hole cut-outs! I wonder where they came from...

And now we see the bowl stand in all of its unfinished glory. The pieces have been cut out, but that's it. Very rough, and with the formica still covering most of the surfaces, gluing them together wouldn't work very well.

So, at this point what I did was clamp the two legs together in an attempt to make them as identical as possible. With them clamped together I went over all the edges to do just that. Lots of sanding time, essential for any project.

With the legs matching up a bit better, I took all of the pieces outside with the belt sander, and removed the formica. It didn't take all that long, but my methodology wasn't perfect, and so some places on the top had peaks and valleys from a lack of uniform sanding. You can't see it, but they're painfully obvious to the touch. Regardless, the stand is pretty much done at this point. All I had to do now was use some wood glue to attach the legs, and it was showtime!

It took Tess a little bit of time to get used to eating out of it, but she adapted quickly. Perhaps more importantly, since I completed this prototype and started using it back in November/December of 2010, from then until now (June 3rd, 2011) Tess has barfed exactly ONCE. So I'd say either she a) grew out of barfing as a natural part of growing older, or b) the bowl stand has done exactly what I wanted, and brought the vomit occurence rate as close to zero as I could have wanted.

So, there are a few problems with the design. First, because the ends are uncovered, Tess can sometimes knock a toy underneath the stand, and I've had a few annoying moments where, in an attempt to get at the toy, she will knock the water bowl out of the stand and onto my carpet. Second, it's not very pretty. I'm not really into aesthetics as a general philosophy, but with the peaks and valleys in the top piece, as well as the unfinished wood look, I'll probably want to revisit this project at some point. Third and finally, Tess is a very messy drinker. I know, I know, cats are supposed to be very clean creatures and all that. Mine isn't. She constantly gets water out of the bowl while she's drinking, and I know that over the long haul, that will eat away at the wood, causing warping and overall structural instability. So what does all this mean? Mostly just that this project is only finished "for now" and will have to be revisited in the future to fix some of these problems. But for now, this prototype works amazingly well and I couldn't be happier.

Thursday, June 2, 2011

Nerf Crossfire again,this time as a surprise gift

With the success I had from making a modified Crossfire for my friend fresh in my mind, I decided to make one for my mom. She'd been over to my apartment a few times, fired off a few Nerf blasters, seemed to enjoy it. And really, who doesn't enjoy shooting suction darts at a window, am I right?

I chose to use a Crossfire for this project for a couple reasons. First and foremost, I had about 5 of them, and I didn't have plans for all of them. Second, they're really cool blasters. They prime by cocking the slide, and have decent ranges and power to boot. It's a win-win! Now, my mom's favorite color is green, so I decided to go with a very simple color scheme of black and green. As is my routine these days, I made a template!

One new thing I did with this blaster is a far more thorough job of sanding off the paint. Previously my sanding consisted of getting rid of the printed phrases "Do not modify blaster," the upraised Nerf logo, and then more or less "roughing up" the rest of the blaster. After reading a few more posts (yes, I read a lot of message board posts, because I always want to do better) I decided to up the ante on this blaster and sand off as much of the stock paint as I possibly could. This accomplishes a few things, from making a much better sticking surface for paint (and especially vinyl dye) to stick to, and also minimizes the "layers of paint" effect you get when you paint layer on top of layer and keep making it thicker and thicker.

One new thing I did with this blaster is a far more thorough job of sanding off the paint. Previously my sanding consisted of getting rid of the printed phrases "Do not modify blaster," the upraised Nerf logo, and then more or less "roughing up" the rest of the blaster. After reading a few more posts (yes, I read a lot of message board posts, because I always want to do better) I decided to up the ante on this blaster and sand off as much of the stock paint as I possibly could. This accomplishes a few things, from making a much better sticking surface for paint (and especially vinyl dye) to stick to, and also minimizes the "layers of paint" effect you get when you paint layer on top of layer and keep making it thicker and thicker.

Blaster is now smooth like baby's bottom. Very nice, yes. At this point you probably know the routine. Take out the air restrictor, stick the pieces on blocks, and it's out to the shed we go.

My plan going in to this blaster was to do a gloss black vinyl dye base coat, and then choose some select sections to do again with a nice glossy green coat of krylon fusion. And so it began.

Unfortunately, that plan didn't go well. Because I was doing this in mid-december, it was quite, quite cold outside, and very rainy.

It's hard to see the rain coming down, but take my word for it, the clouds are dumping buckets. As for the cold, well, this is what I looked like during the process.

Yes, I have a respirator now. More on that later. Back to the project at hand, the vinyl dye, either because I had screwed up some part of the process, or more likely due to the cold and poor humidity, didn't cure even remotely close to how it should look. It might be hard to see in the pictures above, but it dried in a very splotchy, non-glossy and non-good looking pattern. I tried to fix it (by rushing the pieces indoors right after application), but it wasn't happening. So, I shifted tactics and since the vinyl dye would serve as a decent base coat (because vinyl dye doesn't add layers or thickness) I applied a light coat of gloss black krylon fusion over it. Success! It didn't have the same curing problems as the vinyl dye, and turned out exactly like I wanted. I could now proceed with the project.

Remember that tiny hole of annoying air leakage from a prior post? Yep, it got epoxy-sealed too. Also, this blaster got taped in the opposite method from the one I did previously for a work friend. Compare and contrast the tape applied, and I think you'll see why the other method is far easier to pull off. Anyway, after applying the green paint all I had to do was wait for the paint to dry completely, and then it was time to put it all back together. Also, learning from my prior Crossfire experience, I did a much more thorough job of sanding down the points of articulation, so this blaster has almost zero paint rub-off. Check it out!

I gave this blaster to my mom on Christmas, not as a holiday gift, but just because it was the next time I saw her after I finished making the blaster. She was thrilled, and enjoys it a lot!

Oh, and as a quick disclaimer, I'm not promoting Rozerem, the plates are just some disposable plates I found at work that I took home to use for stuff like this.

Anyway, as my final thought I'm going to talk about my respirator. This project was one of the first ones I was able to use my respirator on, and it's fantastic. Before this I hadn't used any sort of air filtration, and I had noticed that after a long day of spray painting in a small, confined space, I would have a massive, raging headache (I don't ever get headaches naturally). So I eventually broke down and bought a respirator. And it is 100% effective. No headache, no more contact high off paint fumes. I should have bought one a long, long time ago. If you plan on doing anything involving spray paint, spend the money to get a good one. Don't buy those stupid little masks you see in the doctor's office, they have been scientifically proven to do exactly nothing. Get one like mine, that actually blocks particles from reaching your mouth and nose. I can't breathe through my nose with it on, I have to use my mouth instead, but it's well worth it to avoid killing off brain cells. Masks are great. /rantoff

I chose to use a Crossfire for this project for a couple reasons. First and foremost, I had about 5 of them, and I didn't have plans for all of them. Second, they're really cool blasters. They prime by cocking the slide, and have decent ranges and power to boot. It's a win-win! Now, my mom's favorite color is green, so I decided to go with a very simple color scheme of black and green. As is my routine these days, I made a template!

Blaster is now smooth like baby's bottom. Very nice, yes. At this point you probably know the routine. Take out the air restrictor, stick the pieces on blocks, and it's out to the shed we go.

My plan going in to this blaster was to do a gloss black vinyl dye base coat, and then choose some select sections to do again with a nice glossy green coat of krylon fusion. And so it began.

Unfortunately, that plan didn't go well. Because I was doing this in mid-december, it was quite, quite cold outside, and very rainy.

It's hard to see the rain coming down, but take my word for it, the clouds are dumping buckets. As for the cold, well, this is what I looked like during the process.

Yes, I have a respirator now. More on that later. Back to the project at hand, the vinyl dye, either because I had screwed up some part of the process, or more likely due to the cold and poor humidity, didn't cure even remotely close to how it should look. It might be hard to see in the pictures above, but it dried in a very splotchy, non-glossy and non-good looking pattern. I tried to fix it (by rushing the pieces indoors right after application), but it wasn't happening. So, I shifted tactics and since the vinyl dye would serve as a decent base coat (because vinyl dye doesn't add layers or thickness) I applied a light coat of gloss black krylon fusion over it. Success! It didn't have the same curing problems as the vinyl dye, and turned out exactly like I wanted. I could now proceed with the project.

Remember that tiny hole of annoying air leakage from a prior post? Yep, it got epoxy-sealed too. Also, this blaster got taped in the opposite method from the one I did previously for a work friend. Compare and contrast the tape applied, and I think you'll see why the other method is far easier to pull off. Anyway, after applying the green paint all I had to do was wait for the paint to dry completely, and then it was time to put it all back together. Also, learning from my prior Crossfire experience, I did a much more thorough job of sanding down the points of articulation, so this blaster has almost zero paint rub-off. Check it out!

I gave this blaster to my mom on Christmas, not as a holiday gift, but just because it was the next time I saw her after I finished making the blaster. She was thrilled, and enjoys it a lot!

Oh, and as a quick disclaimer, I'm not promoting Rozerem, the plates are just some disposable plates I found at work that I took home to use for stuff like this.

Anyway, as my final thought I'm going to talk about my respirator. This project was one of the first ones I was able to use my respirator on, and it's fantastic. Before this I hadn't used any sort of air filtration, and I had noticed that after a long day of spray painting in a small, confined space, I would have a massive, raging headache (I don't ever get headaches naturally). So I eventually broke down and bought a respirator. And it is 100% effective. No headache, no more contact high off paint fumes. I should have bought one a long, long time ago. If you plan on doing anything involving spray paint, spend the money to get a good one. Don't buy those stupid little masks you see in the doctor's office, they have been scientifically proven to do exactly nothing. Get one like mine, that actually blocks particles from reaching your mouth and nose. I can't breathe through my nose with it on, I have to use my mouth instead, but it's well worth it to avoid killing off brain cells. Masks are great. /rantoff

Blasters for friends, Nerf Crossfire

At this point in my nerf blaster adventure, I had acquired several blasters, and modified/painted three of them, as you've read previously (in theory). I've also picked up a few tips and tricks, such as good spray paints, and the advantage of making a preliminary template. At this point I'd pretty much devoted myself to the hobby. I've always been a fan of fiddling around with making stuff, and my previous endeavors at translating the thoughts in my head to physical reality haven't gone well. But taking an existing object, modifying it, making it look sweet? I'm there, and I can actually do it!

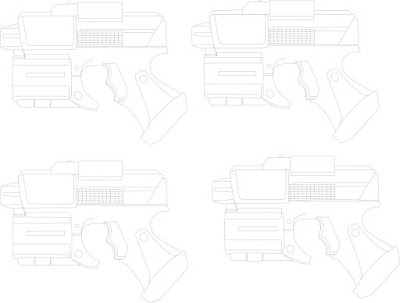

Anywho, I started crusining eBay's listings every couple of days, looking for cheap, cool-looking blasters I could pick up that I didn't already have. What happened is that I expanded my Nerf collection pretty drastically with only a few purchases. One of the blasters I picked up several of is called the Crossfire/Strikefire. Sold solo, it's a Crossfire. Sold as part of a multi-pack promoting the "old" dart tag stuff, it's a Strikefire. Same blaster, different packinging I guess. Anyway, here's what it looks like.

The blaster in the picture is blue, but there are 3 other stock color options of red, green, and orange. Regardless, because of my prior Nerf blaster fun, a friend of mine at work asked if I could make her a tricked out blaster. I said sure (naturally) and she chose the Crossfire as her model of choice. With my new method of creating a template, I gave her a print-out and some colored pencils, and with that I had my color palette. Because of the colors she chose I'll be using Krylon Fusion again, because of the limited color choices with Vinyl Dye. Work start!

Oh look, it's the insides. This blaster started life colored red...but that will soon change. Muh ha ha!

As usual, the air restrictors were the first thing to go. For this blaster it's really easy to remove. Simply take this part of the barrel out, and drill straight through the back. First shot is pre-hole, second is after drilling finished.

Some blasters have this sort of tiny hole in the barrel, ostensibly as another method of preventing some power. Epoxy that sucker closed. More power, more fun!

Now that the basic modifications are done, it's time to rough up the body and remove some bits that will hamper the paint from sticking. Once that's done, it usually looks something like this.

At this point all that remains is to tape the pieces to foam blocks and move them all to the designated painting party palace. Once there, work begins!

For this blaster, I decided to work it a bit smarter. I'd read a few tutorials on better painting procedure, and lo and behold, it made perfect sense. Basically, the idea is to paint the body whatever color will be used for the "secondary" and smaller parts. Once that dries, those small parts get taped up and sealed, and then you -repaint the body with whatever color it should be at the end. Might sound a bit backwards, but it's astoundingly easier to do it that way instead of the reverse. This is because way too often, those small pieces are really hard to tape off such that their color doesn't get on the bigger sections, but it works great to do it this way.

See how nice that looks? I'm a big fan of this method now. Anyway, at this point it's time for a light coat of clearcoat to help preserve the paint and attempt to diminish the rub-off tendencies of this particular model.

At this point the blaster is done being painted, and just needs to be put back together.

I really like how it turned out. I didn't sand the slide down quite enough, so there's a bit of paint rub-off there, but my friend doesn't mind. All in all, she has seemed to be quite delighted with how it turned out, and so am I. First commission, finished!

Anywho, I started crusining eBay's listings every couple of days, looking for cheap, cool-looking blasters I could pick up that I didn't already have. What happened is that I expanded my Nerf collection pretty drastically with only a few purchases. One of the blasters I picked up several of is called the Crossfire/Strikefire. Sold solo, it's a Crossfire. Sold as part of a multi-pack promoting the "old" dart tag stuff, it's a Strikefire. Same blaster, different packinging I guess. Anyway, here's what it looks like.

The blaster in the picture is blue, but there are 3 other stock color options of red, green, and orange. Regardless, because of my prior Nerf blaster fun, a friend of mine at work asked if I could make her a tricked out blaster. I said sure (naturally) and she chose the Crossfire as her model of choice. With my new method of creating a template, I gave her a print-out and some colored pencils, and with that I had my color palette. Because of the colors she chose I'll be using Krylon Fusion again, because of the limited color choices with Vinyl Dye. Work start!

Oh look, it's the insides. This blaster started life colored red...but that will soon change. Muh ha ha!

As usual, the air restrictors were the first thing to go. For this blaster it's really easy to remove. Simply take this part of the barrel out, and drill straight through the back. First shot is pre-hole, second is after drilling finished.

Some blasters have this sort of tiny hole in the barrel, ostensibly as another method of preventing some power. Epoxy that sucker closed. More power, more fun!

Now that the basic modifications are done, it's time to rough up the body and remove some bits that will hamper the paint from sticking. Once that's done, it usually looks something like this.

At this point all that remains is to tape the pieces to foam blocks and move them all to the designated painting party palace. Once there, work begins!

For this blaster, I decided to work it a bit smarter. I'd read a few tutorials on better painting procedure, and lo and behold, it made perfect sense. Basically, the idea is to paint the body whatever color will be used for the "secondary" and smaller parts. Once that dries, those small parts get taped up and sealed, and then you -repaint the body with whatever color it should be at the end. Might sound a bit backwards, but it's astoundingly easier to do it that way instead of the reverse. This is because way too often, those small pieces are really hard to tape off such that their color doesn't get on the bigger sections, but it works great to do it this way.

See how nice that looks? I'm a big fan of this method now. Anyway, at this point it's time for a light coat of clearcoat to help preserve the paint and attempt to diminish the rub-off tendencies of this particular model.

At this point the blaster is done being painted, and just needs to be put back together.

I really like how it turned out. I didn't sand the slide down quite enough, so there's a bit of paint rub-off there, but my friend doesn't mind. All in all, she has seemed to be quite delighted with how it turned out, and so am I. First commission, finished!

Subscribe to:

Comments (Atom)